Polyurethane Foams: Nature as a Model

The fact that foamed material gains mass, but not weight, while remaining extremely stable has been known since before the discovery of polyurethanes. Like many technical achievements, polyurethane foams are borrowed from nature.

The principle of foam with natural ingredients can be observed very clearly in bread. If you add yeast to the dough, the yeast fungi produce carbon dioxide as they multiply. While the dough is resting, what is commonly known as carbon dioxide is produced inside. After baking, only the small cavities created by the gases remain inside the bread.

The human bone structure shows just how practical such a foam structure can be. In view of the mass we have to carry, our skeleton is rather sparse. We have an enormous number of bones, some of which are very delicate, which only work so well together because they are extremely stable and yet light. The reason for this is that our bones only have a stable and solid shell on the outside. On the inside, they are filled with bone marrow, which is interspersed with small cavities - a natural, stabilizing foam filling, so to speak.

The First Foamer Was a German

Otto Bayer is considered the discoverer of polyurethanes. In 1937, a research group led by the German chemist, who incidentally is not related to the founder of Bayer AG, succeeded in synthesizing polyurethane for the first time. The discovery took place under the roof of the I.G. Farben plant in Leverkusen.

I.G. Farben was a merger of eight German companies, including BASF and Bayer AG. At times, I.G. Farben was the largest company in Europe and the largest chemical and pharmaceutical company in the world. However, this growth was also due to the fact that the company profited from the forced expropriation of Jewish competitors during the National Socialist era.

War Puts the Brakes on Polyurethane

Just a few years after its discovery, industrial polyurethane production began in 1940. However, a real market did not develop at first. Due to the shortage of raw materials during the Second World War, polyurethane was initially only used in the arms industry, particularly in aircraft construction. Only after the end of the war was the plastic available for the civilian market.

In 1960, over 45,000 tons of polyurethane foams were already being produced, including for the mattress industry. In the years that followed, the market for all types of polyurethane grew continuously. In 2007, global consumption amounted to more than 12 million tons - and the trend is rising.

What Exactly is Polyurethane?

Polyurethane is created by mixing two liquid components: Isocyanate and a polyol. Polyols are a group of organic compounds that the food industry uses as sweeteners instead of sugar, for example. You may be familiar with them from sugar substitutes such as sorbitol or xylitol. Isocyanate is the ester of isocyanic acid. The industry mainly uses isocyanate to produce polyurethanes.

When a polyol is mixed with isocyanate, the polyaddition reaction that gives it its name produces polyurethane. If this takes place in an environment in which water is present, for example in the form of humidity, gas is also produced, which leads to the formation of foam. However, polyurethanes are also used to produce hard plastics, for example to manufacture housings for electronic devices or fittings in the automotive industry.

Polyurethane is everywhere

Polyurethanes can take on a wide variety of forms depending on how they are processed. They can be found in many everyday objects, such as kitchen sponges, furniture upholstery or heat-insulating foam panels for house construction. In fact, the construction industry ranks first (as of 2007) among the sectors that process the most polyurethane due to its insulating materials. It is closely followed by the furniture industry (upholstery including mattresses) and the automotive industry (e.g. interiors).

Even less obvious things such as the insides of skis or the wheels of inline skates and skateboards are made of polyurethane. Running shoes usually cushion our joints on foam rubber soles made of polyurethane and the studs of modern soccer boots are also made of it. Because polyurethane is easy to process and shape, the material is also very popular in product design - initial prototypes are often made with it. In a completely foam-free form, polyurethanes are also used as adhesives or coatings: You can find polyurethane in DIY stores as PU furniture clearcoat. It is used as a colorless protective coating for wooden furniture, for example.

How Polyurethane Becomes a Mattress

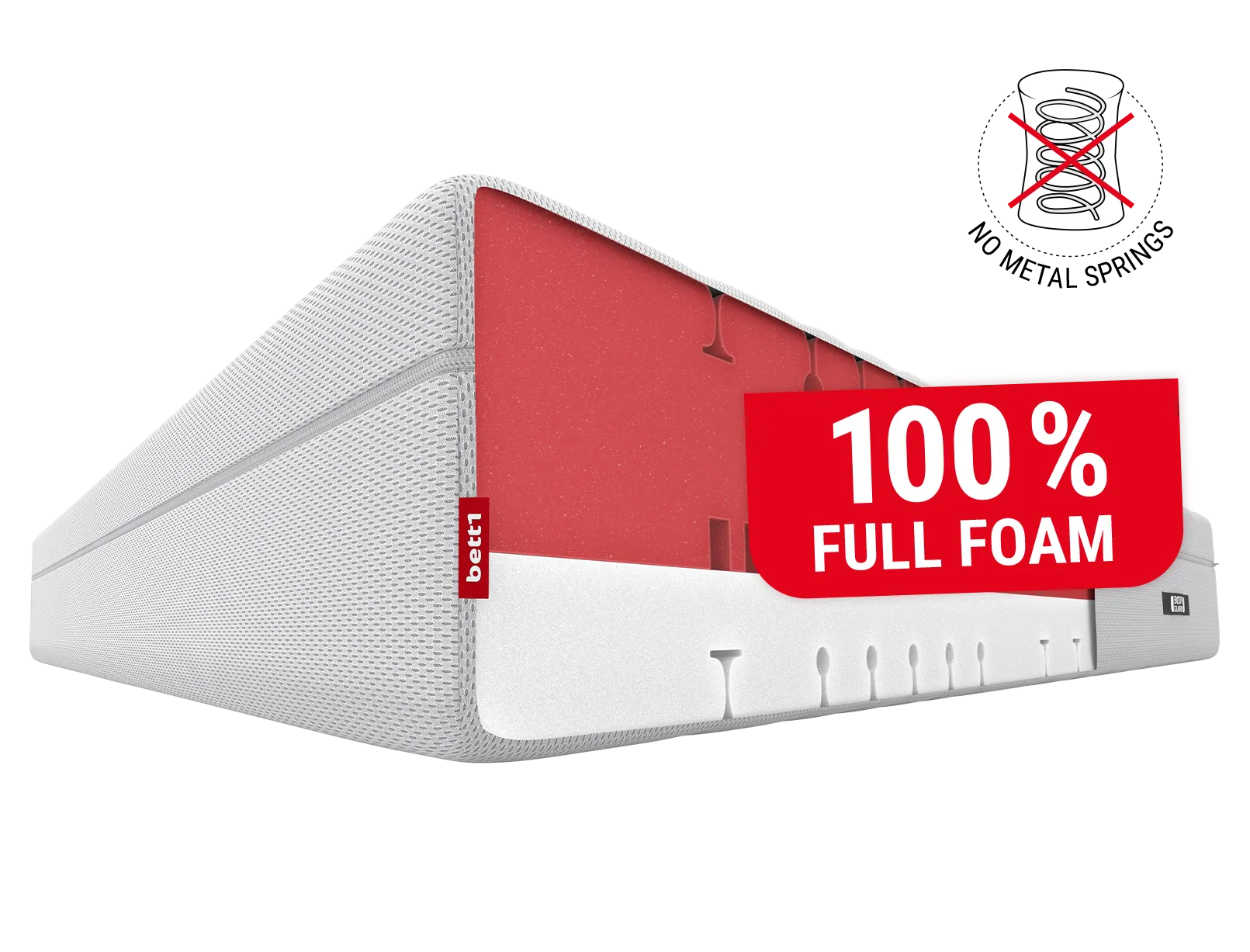

Before a polyol and isocyanate become a mattress or, more precisely, a mattress core, a number of steps are necessary. How this works in detail is usually a trade secret. However, the basic principle is simple and obvious due to the foamability of polyurethanes: a foam is created. The composition of the individual ingredients and the external conditions determine the exact result, such as the degree of hardness or the stability of the foam.

In some mattresses and especially in the production of car seats, the liquid starting material is poured into a mold and foams up perfectly shaped into the finished product. Normally, however, the liquid mixture is first allowed to foam up into a large block and is then cut to the desired shape. After the mattress core has been allowed to air out, the mattress cover is still missing and the mattress is ready. The German TV show “Sendung mit der Maus” captured this simplified manufacturing process in a video years ago.

Polyurethane Foams for Mattresses

Three different foams are made from polyurethane for the mattress industry. The easiest to produce is comfort foam. This sounds promising, but this foam often does not offer the best lying properties compared to other foams. Comfort foam is sometimes simply called PU or PUR foam, which stands for nothing other than polyurethane foam. This name is confusing, as cold foams and QXSchaum® are also polyurethane foams.

Three different types of foam are manufactured from polyurethane for the mattress industry. Comfort foam is the easiest to produce. This sounds promising, but compared to other foams, it often does not offer the best lying properties. Comfort foam is sometimes also referred to as PU or PUR foam, which stands for nothing other than polyurethane foam. This designation is confusing because cold foams and QXSchaum® are also polyurethane foams.

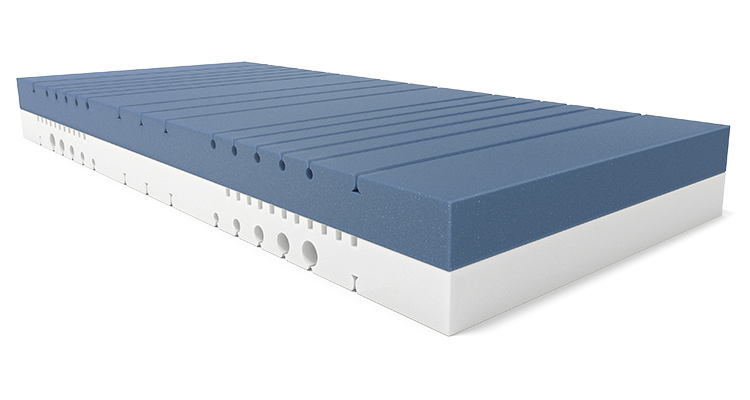

Cold foam is more complex to manufacture and is generally of higher quality than simple comfort foams. The name cold foam comes from the fact that the foam is foamed cold. In the past, a distinction was made between hot and cold foams, but today almost all mattress foams are cold-foamed – yet the name cold foam has remained. Mattresses with a cold foam core usually provide good support for the body, but sometimes do not have the longest lifespan. In individual cases, this may be because some cold foams are not breathable enough, causing moisture to accumulate inside. As a result, the foam structure can collapse and dents can form in areas that are subject to particular stress. However, this phenomenon cannot be generalized; good mattresses can also be made with a cold foam core.

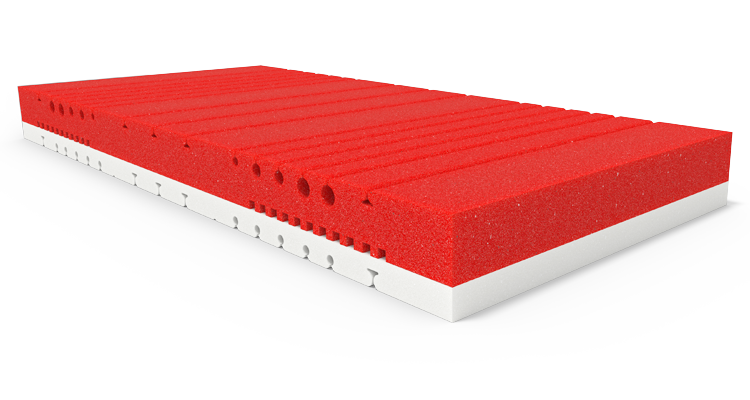

Beim QXSchaum® is a further development of conventional cold foam. The manufacturing process has been optimized to such an extent that the various degrees of hardness can be easily reproduced. QXSchaum® also has a particularly open-pored cell structure, which allows moisture generated during the night to evaporate more easily. There is therefore no moisture accumulation with QXSchaum®, which promotes longevity. That is why we offer a ten-year warranty on the mattress core of BODYGUARD® mattresses.

The Myth of Density

It is still claimed in the mattress industry that the density and quality of mattress foams are directly related. The higher the density, the more material is used and the more stable the mattress core is. Or so the claim goes. The BODYGUARD® mattress proves that there is nothing to this myth with its light density combined with high durability and quality.